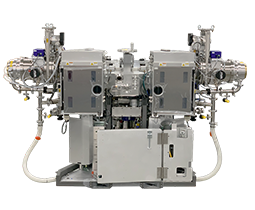

Ferrotec 的 MeiVac MCT-8000 枚葉式RF Diode濺鍍系統是可於直徑200mm的基板上進行Al2O3、SiO2、Ta2O5等金屬氧化物薄膜的成膜作業,濺鍍沈積速率高達950A/min,是量產型枚葉式系統。本系統係特別針對HDD讀寫頭方面的應用進行優化,但在其他例如化合物半導體領域中亦具備極高的應用潛力。

MCT-8000的系統色特如下:

- 可相容於無塵室作業環境:透過隔離的前面板將主系統與無塵室的生產作業區分離

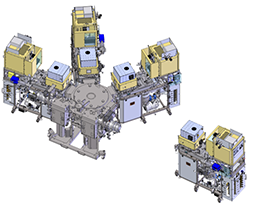

- 採模組化設計:可依照產能需求彈性進行擴充

- 高度自動化:採用Brooks MX-600枚葉式平台,搭配Mag 7機械手臂作業

- 生產製造:內建可程編之SECS/GEM,可與Fab的MES系統連線作業

MeiVac MCT-8000 枚葉式濺鍍系統的部分規格羅列如下:

- Production-proven 24/7 cluster tool

- Fully automated processing of up to 200mm ∅ substrates

- Available with 2 to 4 process modules and with 2 load-locks

Process modules are field retrofittable - Brooks MX-600 cluster platform with Mag 7 robot

- Every chamber has a dedicated slot valve and pump stack with turbo & water pump

- Cassette present sensor, wafer present sensors, and wafer slideout sensors

- Aligner with notch detection and orientation

- Wafer temperature sensor

- Integrated RGA for system control

- Optimized for Hard Disk Drive Thin Film Head application

- Al2O3, SiO2, Ta2O5…

From 0.2μ to 23μ for Al2O3

O2 process capable for enhanced side wall coverage - <1.0% sigma/mean uniformity and layer concentricity

- High rate deposition processes (>950A/min)

- Proprietary, multi-MFC gas distribution system for process modules

- Helium backside gas cooling

- RF substrate bias option to enhance deposited film properties

- Available for metal or reactive dielectric material deposition

- Windows 7 based UI and GE RX3i Programmable Logic Controller (PLC)

- Profibus communications to key components on the system

- Configurable SECS/GEM option for communication with most fabs’ Manufacturing Execution Systems (MES)